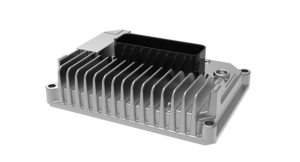

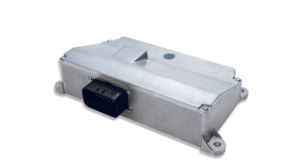

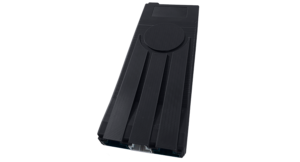

OpenECUTM Electronic Control Units

Dana’s line of ECUs for rapid prototyping and production

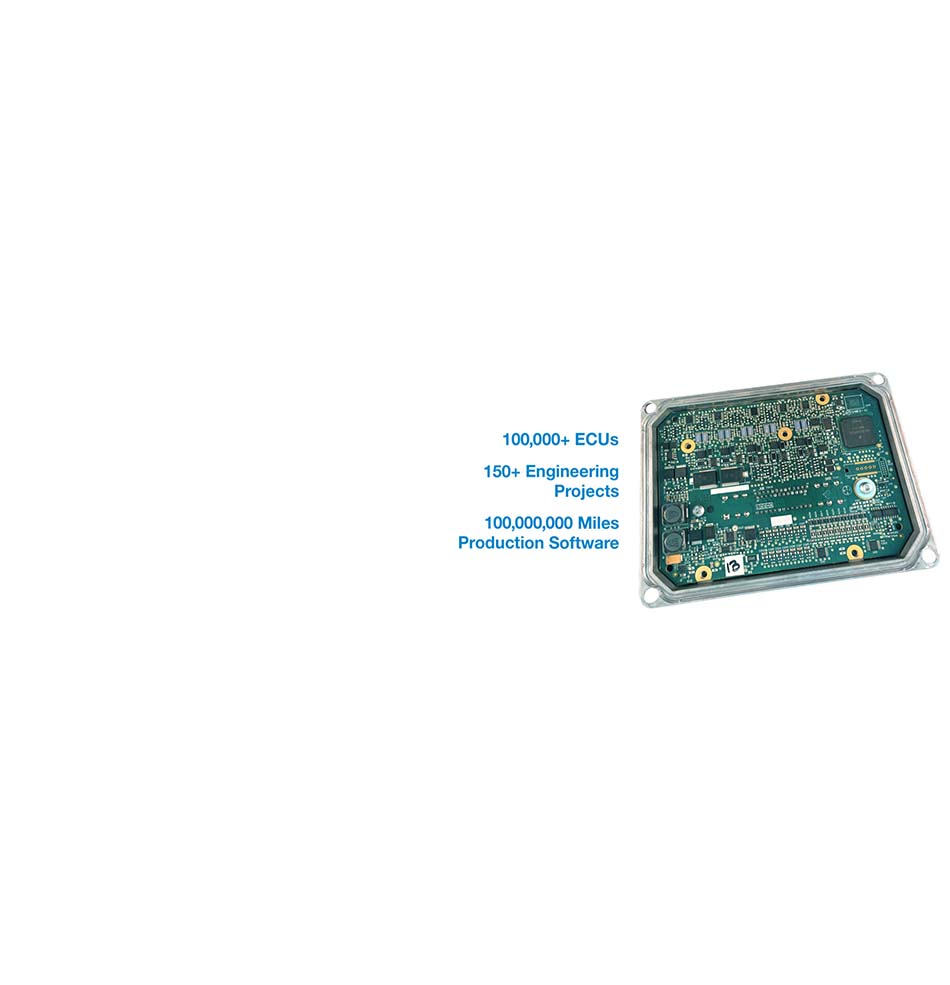

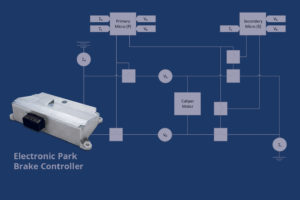

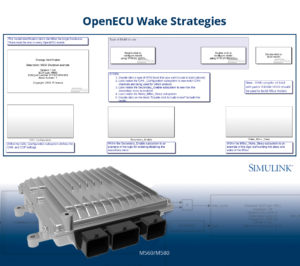

Dana’s off the shelf Electronic Control Units (ECUs) are designed to allow for customization, and are manufactured to automotive volume production standards. OpenECU products enable reliable, efficient and fast embedded controls development and is a cost-effective solution for low to medium volume production applications.

Dana offers OpenECU products as off-the-shelf solutions and can also deliver optimized solutions based on the underlying technology.